Analysis for Energy Efficiency of the Algae Façade

ⓒCopyright Korea Institute of Ecological Architecture and Environment

Recently, energy generation using algae technology is being promising due to the emerging issues on energy insufficiency and environmental contamination, although the solution has not been resolved in aspect of technological and economical efficiencies since it was originally proposed in the early 1980s by many scholars. The energy production technology using algae materials has great values as not only a solution for new energy generation but also an eco-friendly sustainable building equipment system. In addition, cultivation tank for algae using water sources seems to play a role as a decreasing system for thermal transmittance on building components. This study aims at investigating the adaptability towards the future sustainable building with algae technology and testifying the energy efficiency of the algae skins by operating a couple of simulation tools to measure building performances for the proposed prototype of the façade system.

Keywords:

Algae Façade, Sustainability, Energy Simulation1. Introduction

Life became comfortable as fossil energy usage rapidly increases after Industrial Revolution but many problems are caused environmentally. Nuclear energy, especially with high energy efficiency, can cause originally dangerous environmental issues and this was checked with the case of Chernobyl accident and Japan's nuclear crisis.

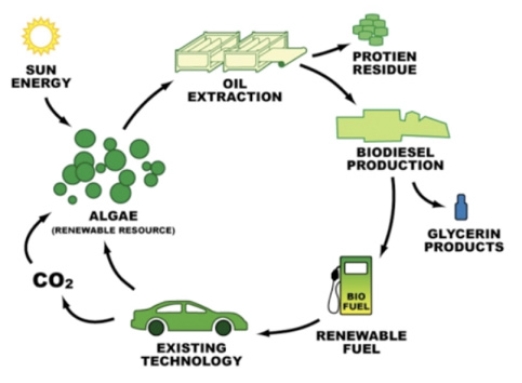

Recently, as concern for the environment increases, new and renewable energy, eco-friendly resource, got much attention and one of this is Algae Fuel using Algae. Algae Fuel is the way using bio-ethanol produced from algae cultivation and energy production technology that can continuously be used once daylight conditions are met.

Besides, Algae Fuel not only produce energy but has positive effects on indoor air quality improvement by absorbing CO2 and emitting O2. Moreover, it is expected that Algae Facade using the water with high specific heat will be very helpful in improvement of thermal efficiency of the building.

Thus, this research explores adaptability of algae, new and renewable energy resource, to the field of architecture and applies Algae to the building surface as new building material that promotes Zero-energy Building ultimately then analyzes the efficiency in the aspect of energy.

The aim of this research lies in investigating and analyzing the features of Algae and preparing standards and utilization guide of architecture field based on them and it contemplated adaptability of sustainable cortex and energy efficiency by comparing and analyzing the office building that Algae was applied and not applied through simulation.

2.The Concept and theory of Algae Technology

2.1.Introduction of Algae Technology

The research about algae popularization went along after 1980s but did not draw much attention because of the problem, inadequate economy. However, it is gaining attention again recently as people become more interested in eco-fiendly new and renewable energy and now related researches are carried out by mainly western countries.

Algae Technology is a photosynthetic organism that produces biomass using light and CO2 in aquatic environment. Algae is largely classified into Macroalgae and Microalgae. Macroalgae is mainly known as seaweed and is a multicellular organism that grows up to 60m fast in sea water or fresh water. Compared to this, Microalgae is a unicellular organism in the unit of micrometer and also grows in sea water and fresh water environment just like Macroalgae but reproduction by nutritive cells is fast.

Algae Technology research until now was mainly composed of basic researches such as characteristic development of birds kind, effector development, however, for the commercialization in the future, high-quality birds cultivation technology and wide-scale bio diesel refinement technology establishment are needed.1)

The reason that technology with worries of economy establishment due to lack of core technology until now has a big potential as eco-friendly building material can be found in the production process and cultivation system of Algae Fuel. If we take a look at production system of Algae Fuel, indoor air quality improvement can be obtained by consuming CO2 and changing it to O2 in cultivation process, moreover, water tank facility for algae cultivation is quite helpful for confidentiality improvement of overall building because of its high specific heat.

2.2.Application of Algae Technology

According to prior researches of Christi (2007), Microalgae is known as better one in the aspect of energy production among two bird types and since it is made of invisible small cells, the water around it tends to be green while Macroalgae contains visible floaters. Thus, considering the energy production aspect and visual aspect oof building based on the fact above at the same time, the general opinion is that it is proper to apply Microalgae to the building.

Many methods are being developed as cultivation method for Microalgae and following two methods are the ones used mainly at the present.

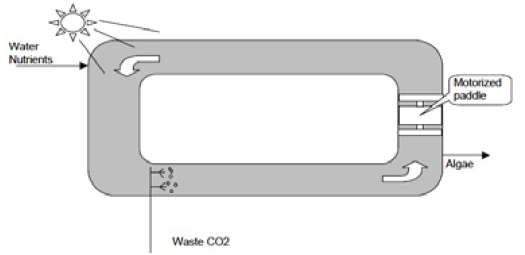

A. Open pond system

Open pond system is a structure that the form of lanes opened to the outside are connected and a system that algae cells and nutrients are mixed then circulated by Paddle Wheel, usually, Baffle is installed to save the space in perimeter. It is a system that produces energy based on the solar energy, so it is general to constitute it with the depth below 30m so that light penetration is good for delivering sunlight to Microalgae is very important.

This technology has been researched by DOE, Department of Energy, for a long time as a cultivation method for Microalgae and Algae Fuel Farm form is generally made in large scale in outer space. This system has its weakness in that it has much moisture loss by evaporation although installment cost and operation cost is cheap and CO2 supply is inefficient. Besides, keeping a stable temperature is quite crucial to maintain high-efficiency energy production amount and this is quite hard to apply to the condition of our country, where we have big temperature gap between quarters.

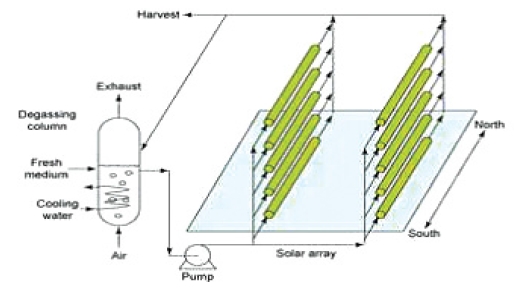

B. Close photobiological effector system

Like Fig. 3, close photobiological effector system uses transparent conduuit that grows Microalgae in the water by supply of CO2 and nutrients as well as light penetration and is the most capital-intensive system. This system is generally installed outside in order to utilize natural sunlight irradiation. The advantages of photobiological effector are that cultivation conditions can be controlled easily and that there is no moisture loss due to evaporation, that contamination from the surrounding environment can be prevented. Especially, biomass efficiency of close photobiological effector is higher by more than 13 times compared to open pond and the concentration of biomass is higher by 30 times, thus production efficiency is excellent compared to yield cost.

Cultivation effector is designed to have large surface compared to its volume and the form that many transparent tubes are connected is most widely used for the structure. The diameter of the tube is usually below 10cm to enable sunlight to penetrate at maximum level. Cultivation medium is circulated within the tube by pump and Microalgae grows by photosynthesis for it is exposed to the light.

Oxygen is generated in the process of photosynthesis. In open lane system, it is no problem for oxygen is emitted to the atmosphere, however, in close system, excess oxygen should regularly be removed for oxygen more than a certain concentration within cultivation medium can depress the growth of Microalgae. Besides, since CO2 is used in the growth of Microalgae, CO2 should continuously be supplied so that ph will not go up or carbon will not be depleted and temperature must be maintained stably with that of night by cooling it while daylight.2)

Judging on these basis, close photobiological effector system can be said appropriate as method to apply algae to the building. Furthermore, it is judged that using the whole surface of windows and doors instead of conduit of pipe shape as lane form to actively transform water with high specific heat to building energy upon usage in the building would make better efficiency.

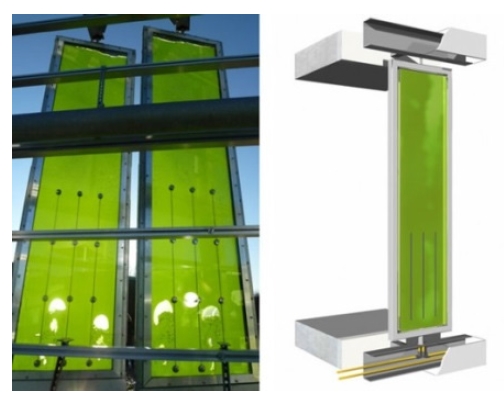

Fig. 4 is a precedent of Algae Façade in Hamburg, Germany. We can know from the case that it has an overall lane form instead of conduit form and that this structure is the one specific heat of lane can be utilized at the maximum level. Thus, this research as well conducted experiment targeting the analysis model that Algae Façade of overall lane form was applied to building facade.

3.Simulation and analysis

3.1.Selection of simulation method

In this paragraph, we would like to discuss the methods of simulation for research conduct. Presently, various simulation methods using parameter regarding target building model and environmental factors are being used for analysis of energy efficiency. The result of comparing and analyzing the pros and cons of representative method to select the optimal experimental methods is as follows.

First, Ecotect can be used by starters through intuitive simulation interface but there is a possibility to lose information for the process retrieving them through IFC/gbMXL is not that smooth. Energy Plus can relatively do precise analysis based on DOE-2 analysis engine but its weakness is that it takes long time to analyze because parameter input is complicated and individual validation is needed.

IES/VE does not support modeling on its own so outer modeling program should be in sync to perform the task, and its advantage is that model of various modules can be used while its weakness is that the expression of analysis result is insufficient. Green Building Studio(below GBS) is a Web-based tool and uploads model information in the method of gbXML/IDFand program that analyzes the energy efficiency when climate and schedule are set. It is easy to analyze but since it should be connected and in sync with management module of server, a certain amount of time is spent in data calculation.

Project Vasari as well uses DOE-2 analysis engine and supports reliable standard value about various parameters needed for analysis as mentioned in Table 1 thus is capable of drawing relatively precise result. Although it cannot do detailed modeling because of features of program developed with the goal of analyzing initial stage in the design, it can print in gbXML form with much compatibility and calculate various result values with easy sync with GBS.3)

This research tried to analyze energy efficiency of Algae Façade applied to general office building type. Here, in order to conduct simulation, various parameter values of office building are needed. Say for example, precise parameter values that can increase the reliability of analysis such as indoor pleasant temperature scope depending on the use type or occupation rate of building according to the time of general office building and Project Vasari, as shown in Table 1, supports verified parameter values through notified bodies. Therefore, this research selects Project Vasari and conducts analysis model tabulation and simulation first then performs additional energy simulation through GBS using parameters provided in secondary.

3.2.Parameter setting and analysis

Based on simulation methods selected above, this research was carried out in the way that compares analyzed result obtained from two simulations which each applied different facade parameter to the same model. The size of the building modeled was set as working space that 200 workers use and land, adjacent building type, climate and other factors that can affect energy efficiency aside from facade energy efficiency are set as control factors.

Project Vasari provides the function that ASHRAE Standard information is put directly upon selecting the region of our country through sync with Google Map. Thus the weather information of this research was set as Seoul that has relatively high distribution of office building and used weather and climate information of the target area.

About the detailed level of modeling, analysis model was made on the basis of Level of Development, LOD, defined by American Institutes of Architects (AIA) since national standard is imperfect and modeling level by each stage can be summarized as Table 3.

This research conducted comparison analysis of energy efficiency between buildings that Algae Façade was applied and general office building through model at the level of LOD 100 for its aim lies in evaluating efficiency from energy efficiency to LCA(Lifecycle Assessment) as building factors, not in evaluating efficiency of building facility.

Analysis model was utilized in the way that analysis result values are compared by classifying and applying the parameters related to the energy efficiency and material of facade that characterizes two comparison objects. Occupation rate of the building, among the data used in the process of analysis, was reflected on the basis of basic data regarding non-residence new building shown in Table 4 and the used time, yearly use schedule and cooling and heating level of user's request were analyzed by putting parameters according to ASHRAE Standard.

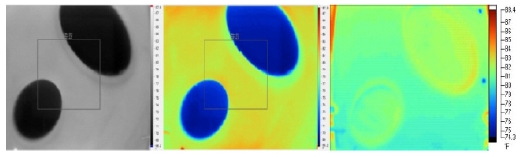

Fig. 5 is an experiment conducted in North Carolina university of U.S.A and recorded thermal energy distribution grasped using infrared camera by producing Mock-up of Algae Façade. In the result of this research, Algae Façade was shown to have same energy efficiency of Low-e Coated IGU(Insulated Glass Unit).

This simulation intended to reflect the U-Value measured in the experiment above according to its principle but since Project Vasari program is not supported with additional U-value editing function, it chose facade data with same U-value with it and went along with it and this as well applies standard value of ASHRAE. To add, energy efficiency parameter of other materials and facility are applied as shown in Table 7-8.

3.3.Analysis result of simulation

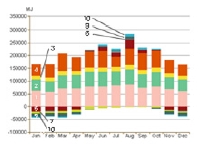

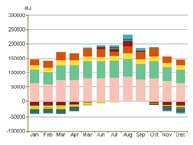

Based on these setting data, we analyzed energy efficiency of Algae Façade through two times simulation which applied facade function of building differently. As a result of simulation, analysis result by energy efficiency factors classified in Table 9-16 was drawn and the summary of major points is as follows.

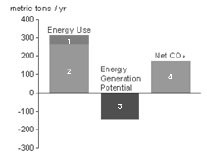

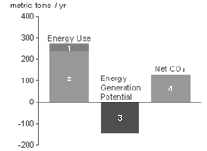

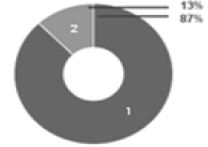

1. Yearly emission quantity of carbon decreased by more than 13%. Table 12 compares the carbon emission quantity by electricity and fossil fuel. The value of analysis result is the value that did not consider CO2 consumed in cultivation tank and it is judged that it would practically exceed 13%.

2. Yearly usage of electricity and fossil has decreased. Table 13-14 is the result of simulation of yearly usage of electricity and fossil. From this result, electricity and fossil usage saved per m2 is relatively shown as 16 kWh/sm/yr, 54 MJ/sm/yr. If we suppose Algae Façade system has been used for 20 years in the aspect of LCA, saved electricity energy is 2,592,930kWh and fossil energy can be shown as 8,957,579 MJ. When this value is compared to the energy usage of general office for 20 years, electricity usage decreases by more than 10% and fossil usage by more than 33%.

It is thought that this result is the result value caused by high specific heat of tank to cultivate Algae Fuel. If constructed realistically, additional energy efficiency decrease is expected for there will be additional energy consumption to keep the cultivation tank and facility, however, when considering the aspect that bio fuel is produced in Algae Façade, it is expected that it could offset this enough through algae cultivation technology and fossil extraction technology enhancement in the future.

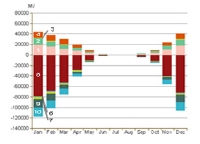

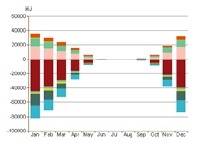

3. Monthly heating and cooling capacity has decreased due to high insulation performance. This can be checked in Table 15 and 16. In the analysis graph, the change in energy demand due to Algae Façade application, regarding all items of Window Conductive and Window Solar, was shown to have decreased monthly heating and cooling capacity in relatively wide range for the model which applied Algae Façade to all items compared to general office.

4.Conclusion

This research conducted expected energy efficiency analysis of building when cultivation tank of Algae Fuel is applied to building facade. The result of conducting simulation and analysis using Project Vasari supported with ASHRAE Standard as parameter input value is as follows.

First, we can expect the effect of carbon emission quantity decrease. Considering CO2 consumed in cultivation tank not to mention the carbon emission quantity of electricity and fossil fuel, it is seen it would exceed this much in real.

Second, we can expect saving effect of electricity and fuel usage. Through production and management technology enhancement in the future, it is expected that amount of energy saved can be increased.

Third, saving effect of cooling and heating capacity can be expected. Both in Window Conductive and Window Solar item, application model of Algae Façade with high insulation performance was analyzed to have wide width of decrease in cooling and heating capacity quite relatively.

Through this research that analyzed basic energy efficiency of Algae Façade, we could see that it has better performance compared to general cortex in the aspect of carbon emission quantity, electricity usage, fuel usage. Although this research could not analyze the effect of factors that algae autonomously produce and consume for it only focused on thermal energy analysis by thermal transmittance, if researches in the aspect of correlation analysis between Algae Façade and indoor air quality, energy production amount of biomass, continue through future researches, it is expected that function of Algae Façade as eco-friendly building material can be analyzed in more detailed way and that alternative guidelines with much potential can be presented for sustainable building embodiment.

Acknowledgments

This research was supported by a grant (13AUDP- B070244-01) from Urban Architecture Research Program (Development of Hanok Technology, Phase II) funded by Ministry of Land and Transport Affairs of Korean Government.

Notes

2) Ministry of Education, Science and Technology, opcit., pp. 80-81

3) Autodesk, Inc., Vasari Project (autodesk.typepad.com)

References

- Ministry of Education, Science and Technology, KISTI, "Using Algae Bio-energy Production Technologies", (2009, Sep).

- Kim, Deuk-Woo, Park, Cheol-Soo, Needs and Issues for Better Use of Building Energy Simulation Tools at Design Stage, Journal of the Architectural Institute of Korea, 28(10), p317-325, (2012).

-

Moon, Jin Woo, Chin, Kyung-Il, Kim, Sang-Chul, Lee, Kwang Ho, Thermal Sensation Based Humidity Controls for Improving Indoor Thermal Comfort and Energy Efficiency in Summer, Journal of Korea Institute of Ecological Architecture and Environment, 14(1), p75-81, (2014).

[https://doi.org/10.12813/kieae.2014.14.1.075]

- Woo, Kyung-Hhun, Kim, Jae-Min, "Development of BIM-Based Building Energy Performance Tool: Samsung Energy Performance (SEP)", Journal of the Architectural Institute of Korea, 25(12), p113-120, (2009).

- Lee, Ji-Young, Lee, Kyung-Sun, Study on Examples of Sustainable Environment Application in Atrium Space, Journal of the Architectural Institute of Korea, 26(9), p123-132, (2010).

- Jeong, In Young, Choi, Yoon Seok, Ahn, Hyun-Tae, Kim, Jeong Tai, Visual Comfort Evaluation of Interior Spaces by Daylighting Systems, Journal of Korea Institute of Ecological Architecture and Environment, 6(1), p17-24, (2006).

- Choo, Seung-Yun, Lee, Kweon-Hyoung, Park, Sun-Kyoung, A Study on LOD (Level of Development) for Development of Green BIM Guidelines - Focused on Energy Performance Estimation, Journal of the Architectural Institute of Korea, 28(6), p37-47, (2012).

- Corpus Christi, Biofuel from Microalgae, Biotechnology Advances, 25, p294-306, (2007).

- Kyoung-Hee Kim, Beyond Green: Growing Algae Façade, ARCC 2013, The Visibility of Research, p500-505, (2013).

- Mustafa Balat, Havva Balat, Recent Trends in Global Production and Utilization of Bio-ethanol Fuel, Applied Energy, 86, p2273-2282, (2009).